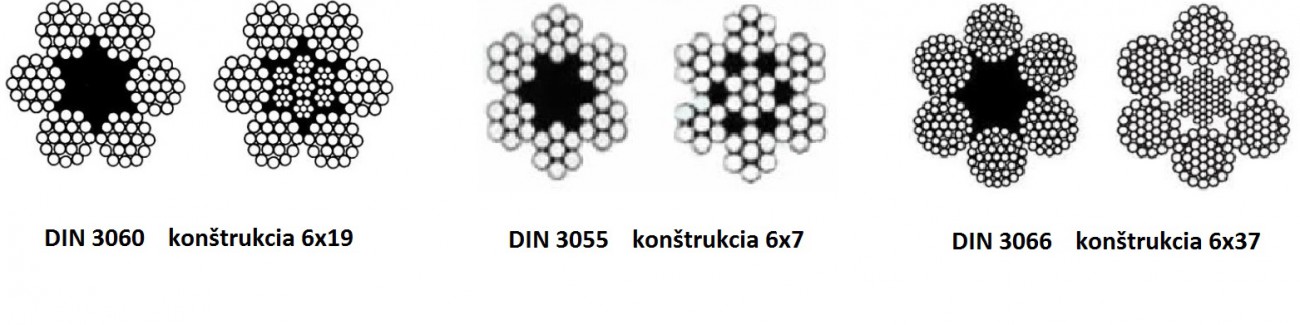

Wire rope slings are built and tested according to EN 13414. Surface of the rope can be treated by galvanization or greased. Standard diameters of ropes are from 6 mms up to 60 mm. Wires are characterized by strength 1770 Nmm2 or 1960 Nmm2. A construction of wire bundles are 6x19 or 6x37, which are entagled around textile or steel core. The most common used wire ropes are those complying with standards DIN 3055, DIN 3060 and DIN 3066.

|

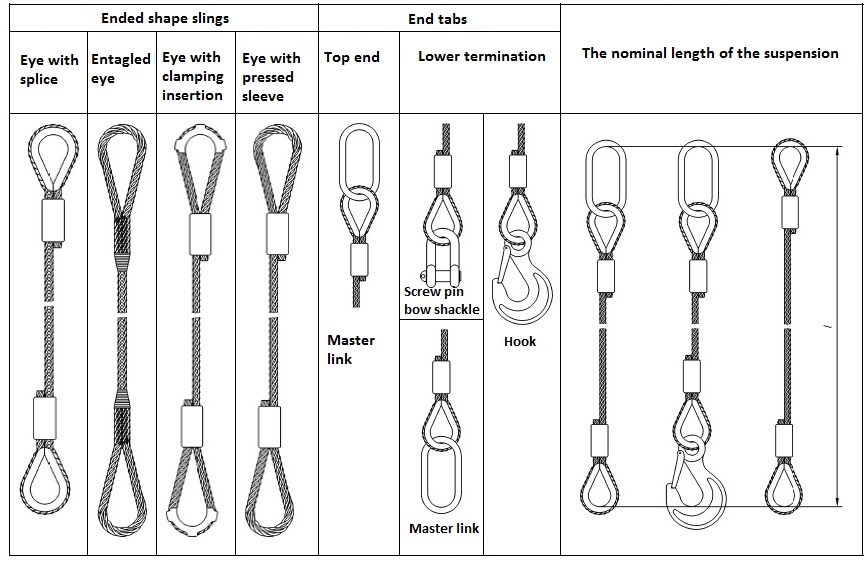

Hanging eyes are created by pressed sleeve (EN13411-3) or by entangled eyes (EN13411-2). Eyes can be soft or strengthened by using clamping insertion or splice (EN 13411-1). |

|

Relevant steel components of grade 8 according to EN 1677 are used for connection of wire ropes slings with hooks and burdens. Following table displays schematically possibilities of assembling of wire rope slings according to EN 13414-1.

Wire rope slings can be safely used in workplace temperature from - 40°C up to 100 °C. Ropes with pressed sleeves from aluminium alloy can not be used in workplace with danger of methane explosion, in workplace with radiant heat and when the burden surface temperature exceeds 60 °C. Wire rope slings can not be dipped into acids or be exposed to acid vapours.

Following table shows the lifting capacity (WLL) of wire rope sling, which eyes were created by pressing, made of wire of strength 1770 Nmm2.